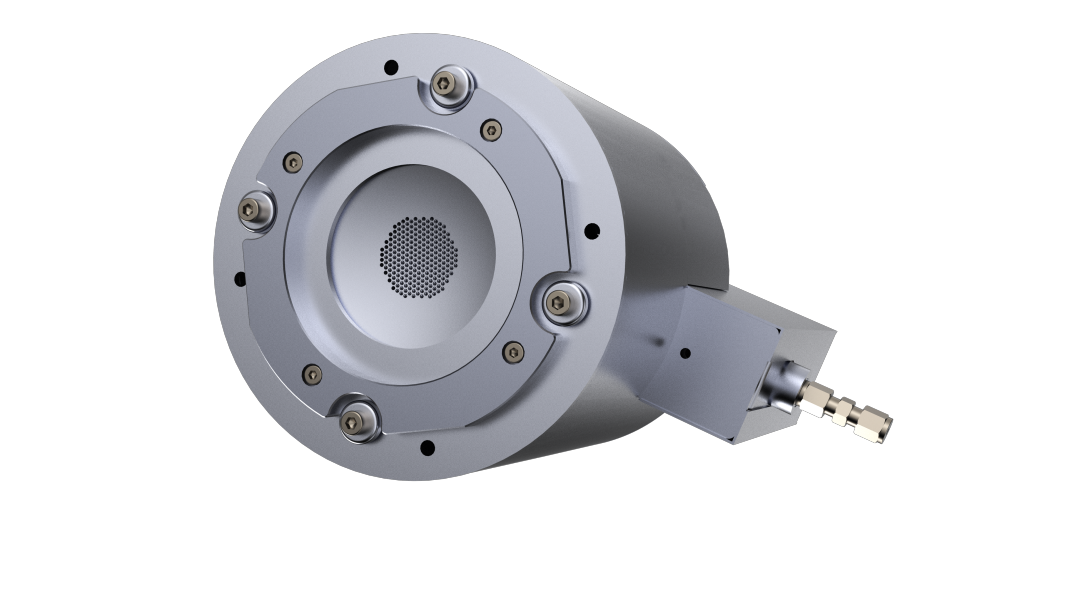

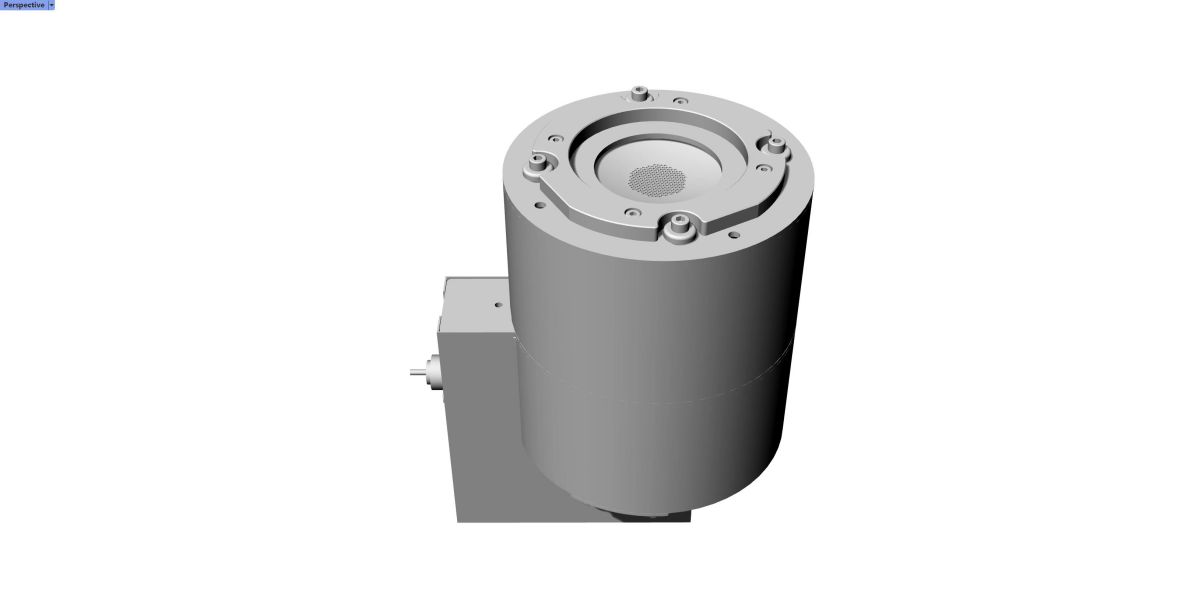

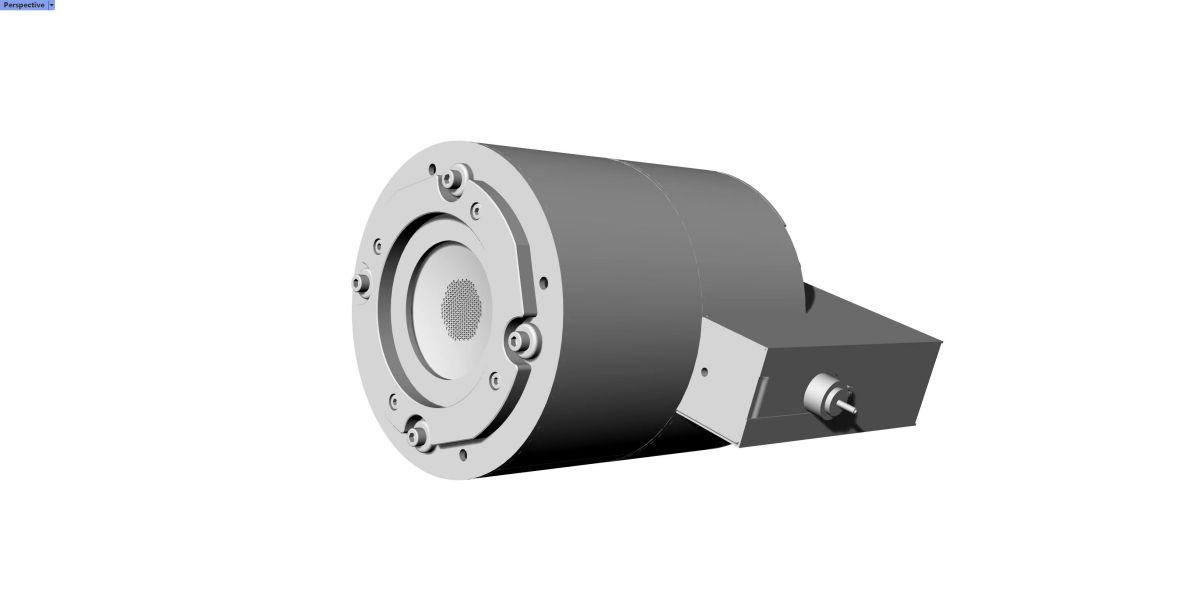

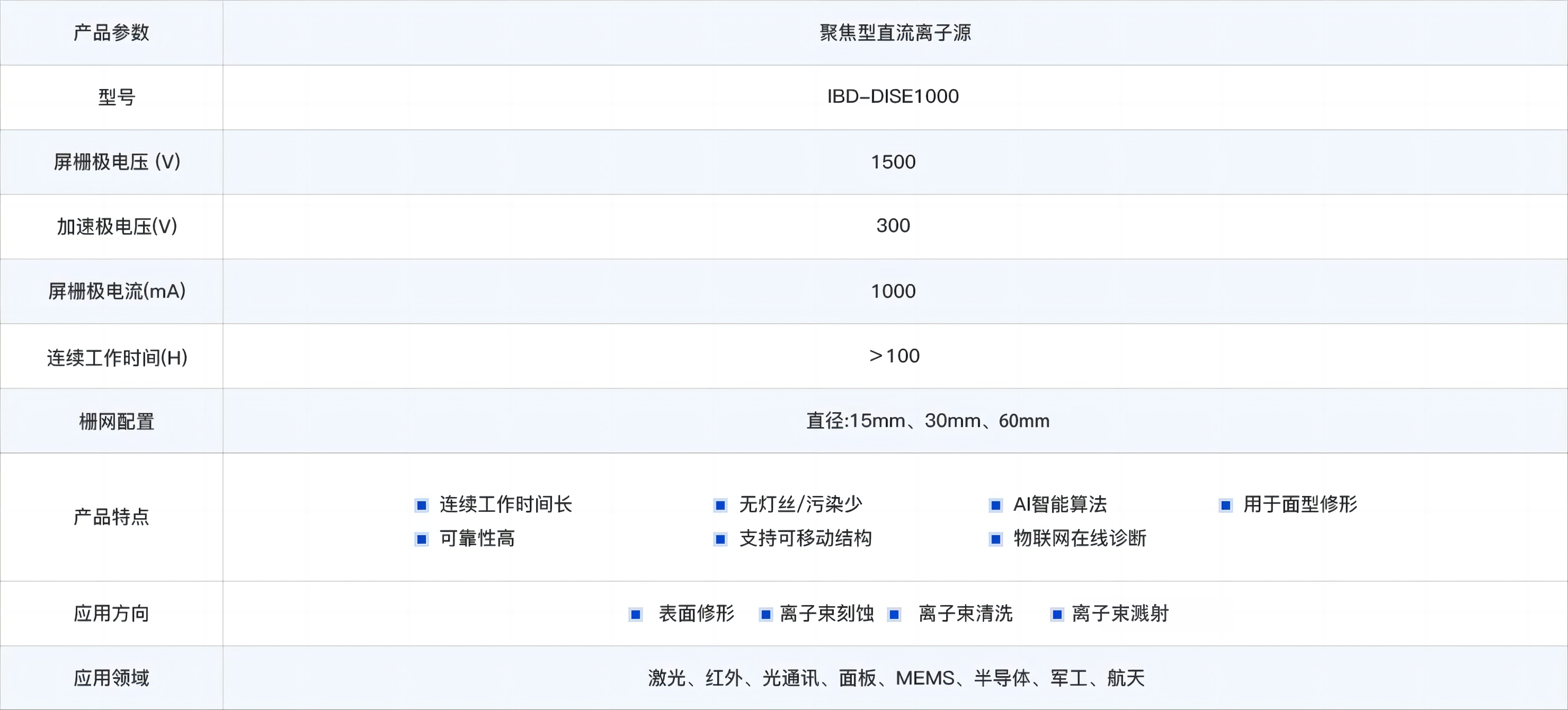

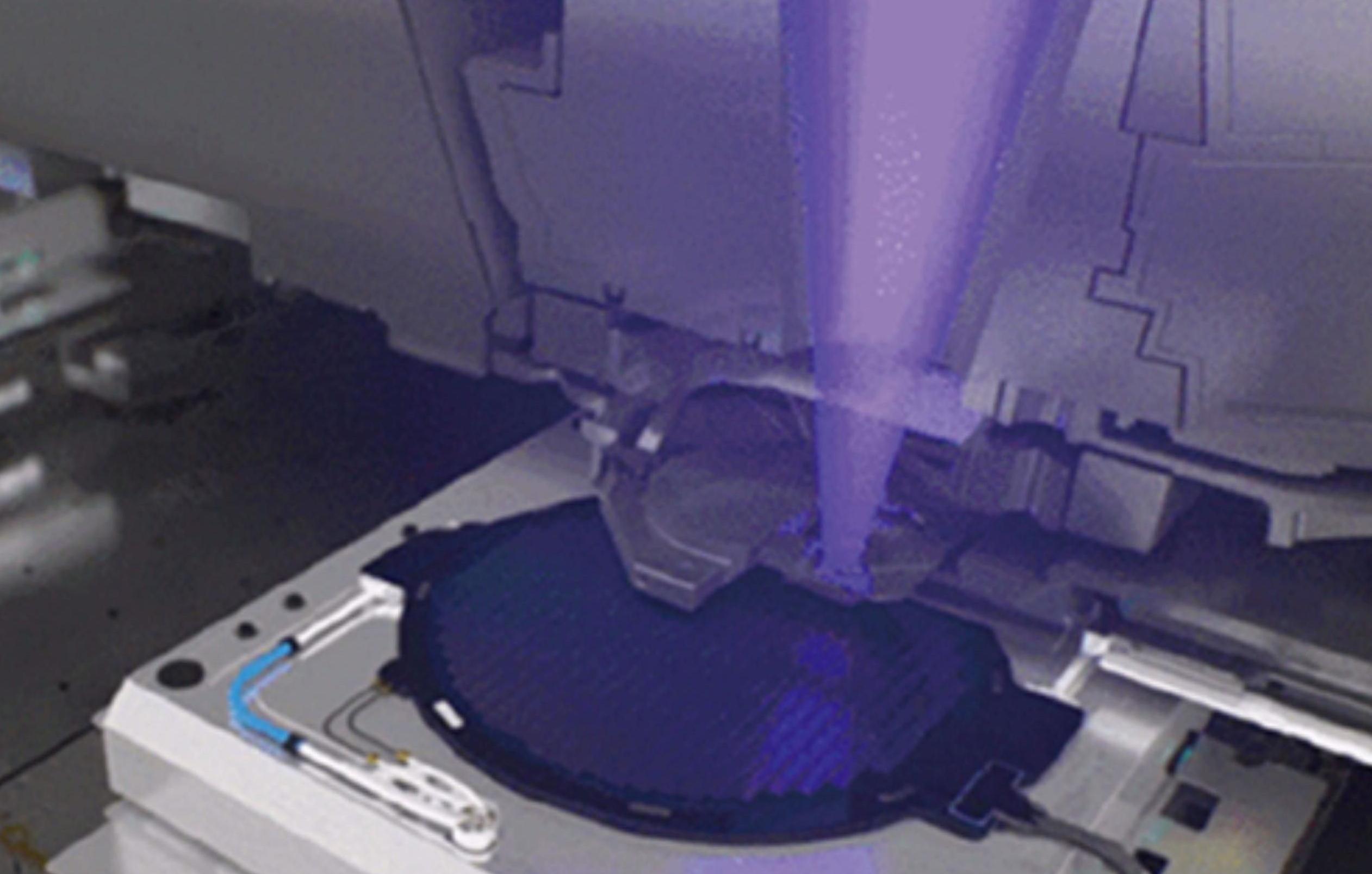

Focused DC ion source

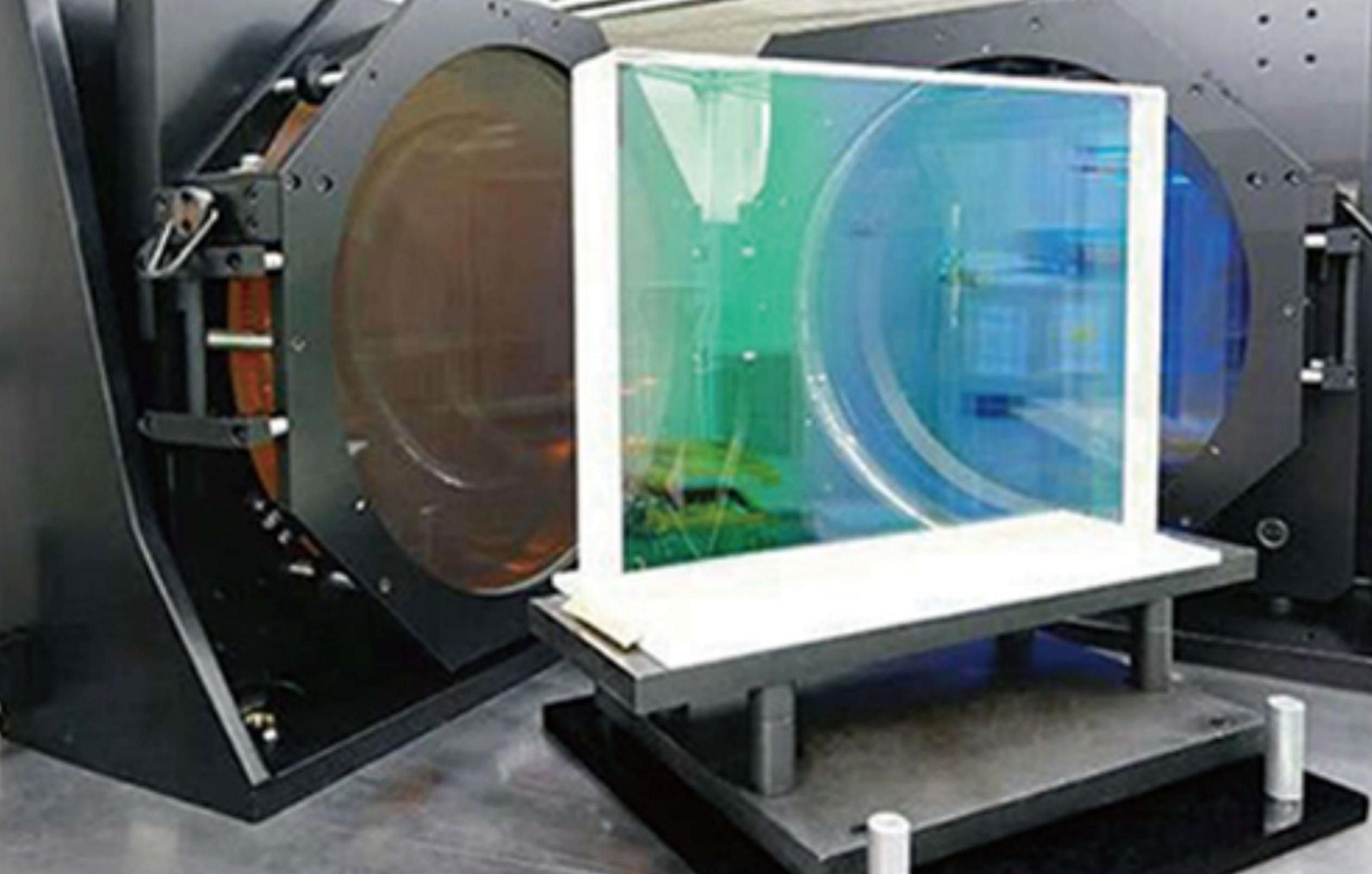

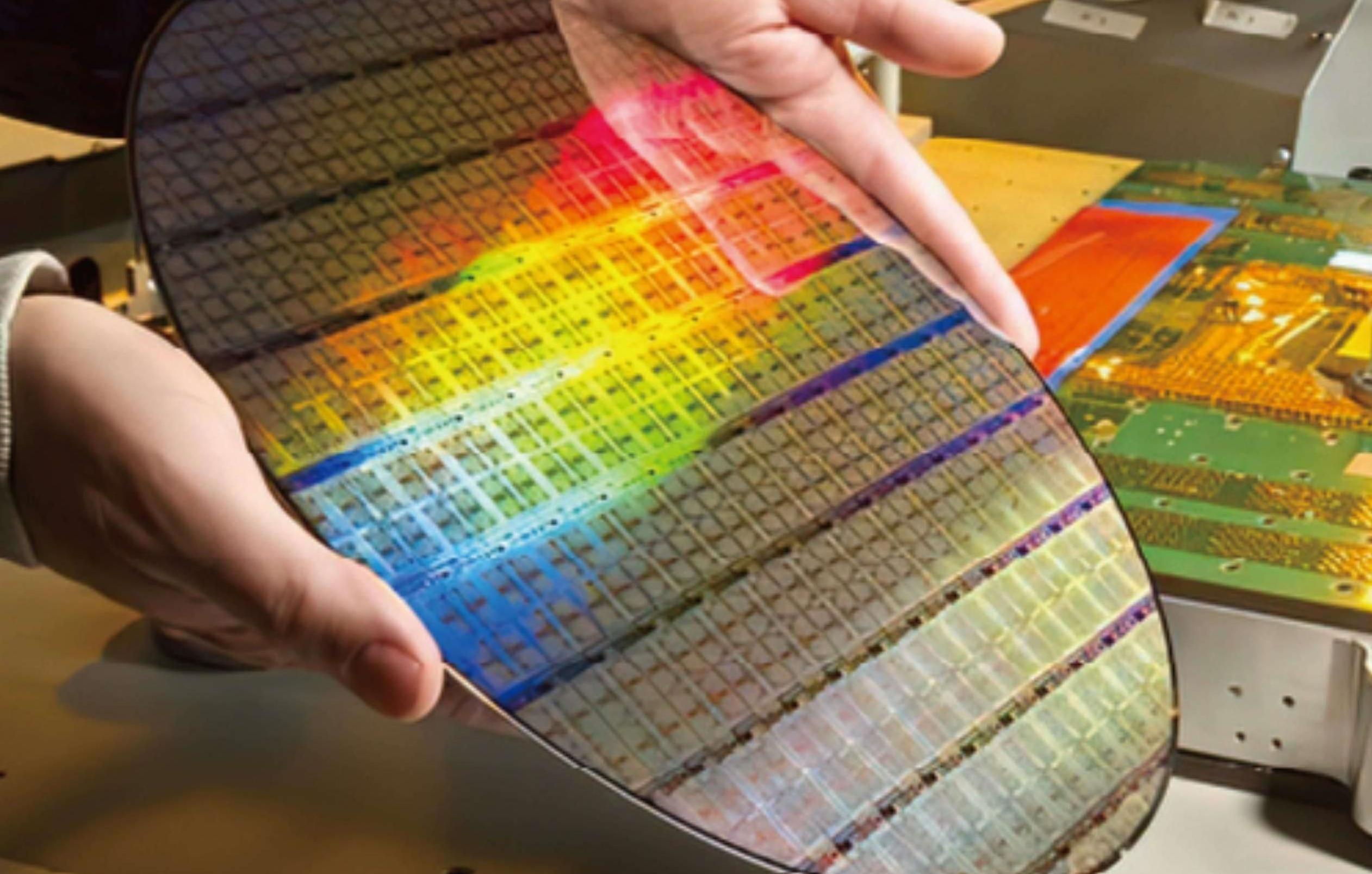

Ion beam shaping and polishing

Ion beam cleaning

Ion beam etching

Ion beam sputtering

Product features

-

Sub-nanometer surface modification

01 -

High energy

02 -

High reliability

03 -

No filament/less pollution

04 -

Low operating costs

05 -

Support for movable structures

06

Product advantages

-

Non-contact sub-nanometer level polishing and repair

Full process normal tracking, precise removal, faster surface convergence

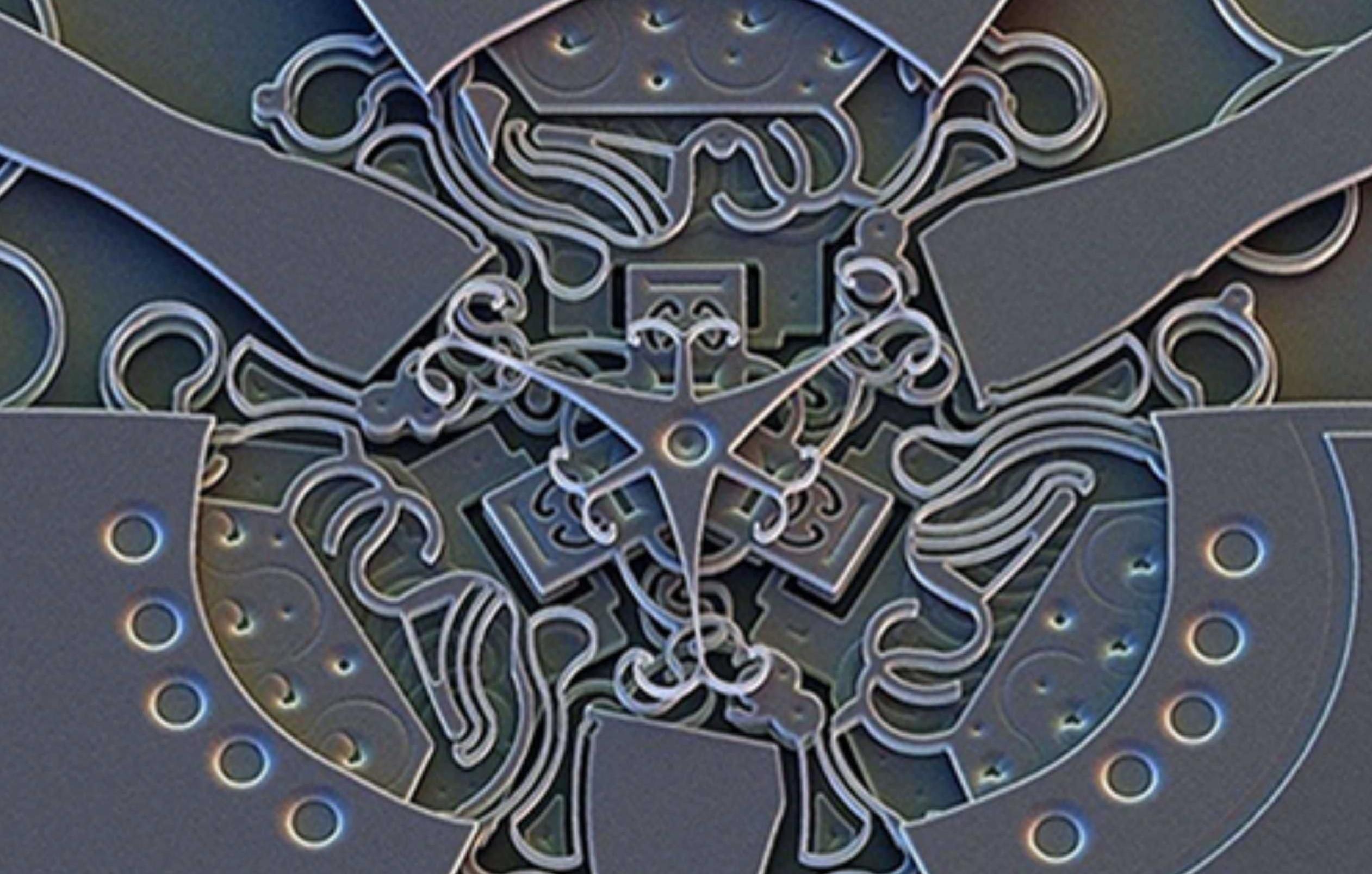

High precision surface correction, RMS up to 1/200 λ

Capable of achieving high-precision polishing capability with surface RMS<3nm

-

Three- or five-axis control system

The shapes of processed optical components include: flat, spherical, aspherical, freeform surface, off-axis aspherical, etc.

Angle compensation function

The materials used for processing optical components include quartz glass, microcrystals, ultra-low expansion glass (ULE), KDP crystals, sapphire, silicon, silicon carbide, infrared materials, etc.

CN

CN

Please scan code to follow us

Please scan code to follow us